January 28, 2025

January 28, 2025

The Oxalic Acid Etch Test is used for the acceptance of wrought or cast austenitic stainless steel materials. Its primary purpose is to provide a rapid qualitative screening method, rather than a definitive rejection criterion. One should note that using this test as a stand-alone evaluation may result in the rejection of materials that would otherwise pass a more thorough hot acid test. Therefore, reliance on Practice A exclusively for material rejection lies outside the intended scope of this method.

The Oxalic Acid Etch Test begins with the preparation of a specimen representative of the material to be evaluated. The specimen is polished to a specified surface finish to ensure a uniform and clear observation of the etched structure. Following this, the polished specimen is electrolytically etched using a solution of oxalic acid. The etching process, conducted under controlled conditions, highlights the microstructural features of the material, making it suitable for subsequent examination.

Once etched, the specimen is analyzed under a metallurgical microscope to observe its microstructural characteristics. The observed etched structure is compared with a set of reference photographs provided in the standard. This comparison helps classify the material into two categories: acceptable or suspect. Materials classified as acceptable exhibit etch structures that indicate resistance to intergranular attack. On the other hand, suspect materials, which may show potential susceptibility, are subjected to further evaluation through specified hot acid immersion tests. These tests provide a more rigorous and quantitative assessment of the material's corrosion resistance.

The Oxalic Acid Etch Test serves as a valuable pre-screening tool for specimens that will undergo more extensive testing under the following practices:

Each of these practices contains detailed tables correlating specific etch structures observed under Practice A to the expected performance of the material in the corresponding hot acid tests. Specimens classified as "acceptable" based on their etch structures can bypass these more time-intensive tests, while those deemed "suspect" must be subjected to the specified hot acid testing protocols for confirmation.

This test is most effective when utilized in conjunction with other evaluation methods mentioned above. Its main objective is to rapidly identify specimens that are unquestionably free of susceptibility to intergranular corrosion (IGC). Materials identified as acceptable typically demonstrate low corrosion rates in hot acid immersion tests, which can span durations of 15 to 240 hours. The Oxalic Acid Etch Test achieves this by classifying etch structures according to established criteria, which are further elaborated in Section 11 of the standard.

The primary advantage of the Oxalic Acid Etch Test lies in its ability to provide a rapid screening mechanism. By employing this test, manufacturers and quality control personnel can quickly identify and accept specific lots of material without resorting to time-intensive and costly hot acid immersion tests. This streamlined approach significantly reduces the overall testing duration and expense associated with corrosion evaluation, making it an efficient tool for ensuring material quality and compliance with industry standards.

Through its rapid classification capabilities, the test enhances the efficiency of the overall evaluation process, ensuring that only materials requiring additional scrutiny undergo more detailed testing. This targeted methodology optimizes resource allocation and reduces unnecessary delays in production and material selection.

The test methodology accounts for two primary classes of specimens: Base metal and Process-affected metal.

Base Metal : Base metal refers to materials free from non-uniform conditions that could alter their corrosion properties, ensuring a more consistent and predictable testing outcome.

Process-Affected Metal : Process-affected metal includes specimens with localized conditions that may impact corrosion properties in a non-uniform manner.

Examples include:

- Welded sections.

- Carburized or nitrided surfaces.

- Oxidized surfaces or regions affected by heat treatments.

- Areas subjected to mechanical deformation.

These localized changes in the specimen can significantly influence the results of other practices, such as Practices B, C, and F. These involve immersing the entire specimen and averaging the mass loss over the total surface area. The presence of non-uniform conditions in process-affected metals introduces variability, making the test outcomes less predictable depending on the proportion and extent of the affected area.

When localized conditions such as welding, carburization, or mechanical deformation are of concern, it is advisable to consider tests that do not average mass loss over the total specimen surface area. In such cases, Practice A (Oxalic Acid Etch Test) or Practice E (Copper-Copper Sulfate-Sulfuric Acid Test) may offer a more precise evaluation of the material's corrosion resistance. These tests provide localized insights into the susceptibility of specific areas, ensuring that the results are not diluted by unaffected regions of the material.

The etching cell is a critical component of the Oxalic Acid Etch Test. It can be constructed using basic components or replaced by a commercial electropolisher or etcher commonly used in metallographic sample preparation, provided the current density requirement specified in the standard is met.

The primary etching solution is a 10% oxalic acid solution, prepared by dissolving 100 grams of reagent-grade oxalic acid crystals (H2C2O2·2H2O) in 900 mL of reagent water. The solution must be stirred until all crystals are fully dissolved to ensure consistency in the etching process.

For specific cases where oxalic acid may not effectively reveal step structures, an alternate etching solution can be used. This solution consists of 100 grams of reagent-grade ammonium persulfate ((NH4)2S2O8) dissolved in 900 mL of reagent water. The ammonium persulfate solution provides a viable alternative for etching materials that may not respond adequately to the standard oxalic acid solution.

The proper preparation and handling of these reagents are critical to achieving reliable and reproducible results during the etching process. These solutions ensure the specimen's microstructures are clearly revealed for classification, enhancing the test's accuracy and reliability.

The preparation and sampling of specimens for the Oxalic Acid Etch Test align with the overarching principles of the specified hot acid tests outlined in ASTM A262-15. Specimen preparation includes processes such as sensitization heat treatment to simulate the material's behavior under service conditions. In addition to these general guidelines, specific instructions tailored to Practice A ensure that the etching process reveals relevant microstructural features for accurate classification.

The recommended test specimen is a cross-section of the material, including the product surface that will be exposed during service. This ensures that the test evaluates the actual material properties relevant to its application. Only minimal surface finishing should be performed, sufficient to remove foreign material while maintaining the integrity of the exposed product surface.

When preparing specimens, a cross-sectional area of 1 cm² or larger is preferred. This size ensures adequate representation of the material’s microstructure. However, if any cross-sectional dimension is less than 1 cm, the other dimension should be at least 1 cm to maintain sufficient material for testing. In cases where both dimensions are less than 1 cm, the full cross-section of the product should be used to ensure that the specimen reflects the material's performance accurately.

Polishing is a critical step in specimen preparation to ensure that the microstructure is adequately revealed during etching. All cross-sectional surfaces should be polished to a fine finish, typically up to CAMI/ANSI 600 grit (equivalent to FEPA/ISO P1200), in accordance with Guide E3. While the aim is to achieve a smooth surface, it is not necessary to remove all scratches completely. The level of polishing required is sufficient to facilitate uniform etching and clear microscopic observation of the etched structures.

Etching should always be conducted under a ventilated hood to ensure safe handling of the gases evolved during the process. The gases released at the electrodes can include entrained oxalic acid, which is both poisonous and irritating to mucous membranes. Adequate ventilation and the use of personal protective equipment (PPE) are essential to prevent inhalation and skin contact with harmful substances.

Etching Process

The polished specimen is etched at a current density of 1 A/cm² for a duration of 1.5 minutes. Achieving the correct current density is critical for uniform etching and accurate results. The following steps ensure compliance with the specified etching parameters:

During the etching process, a yellow-green film forms on the cathode, which increases the electrical resistance of the cell. To maintain optimal conditions, periodically rinse the interior of the stainless steel cathode or container using an acid, such as 30% nitric acid (HNO3), to remove the film and restore conductivity.

As the etching process progresses, the temperature of the oxalic acid solution naturally increases. It is essential to keep the temperature below 50°C to prevent adverse effects on the etching process or specimen integrity. This can be achieved by alternating between two containers:

The rate of temperature rise depends on the total current passing through the etching cell. To minimize heating, the area to be etched should be as small as possible while meeting the test requirements.

Care must be taken to avoid immersing the clamp holding the specimen in the etching solution. This precaution prevents contamination of the solution and ensures the uniformity of the etch across the specimen surface.

After etching, the specimen must be rinsed thoroughly:

Specimens containing molybdenum, such as AISI 316, 316L, 317, and 317L, may not reveal step structures effectively when etched with oxalic acid. For these alloys, an alternate electrolyte consisting of ammonium persulfate (see Section 8.1.1) can be used. Etching in this solution at room temperature for 5 to 10 minutes with a current density of 1 A/cm² reliably develops step structures, even for alloys that are free of chromium carbide sensitization.

The classification of etched structures is a critical step in the Oxalic Acid Etch Test. This process involves meticulous examination of the etched surface to determine the susceptibility of the material to intergranular attack. The classification process ensures consistent and reliable identification of microstructural characteristics, enabling effective evaluation of material performance.

Etched surfaces are examined under a metallurgical microscope to identify the characteristic features of the material's microstructure:

The choice of magnification depends on the type of material and the specific features being analyzed.

To ensure accurate and thorough analysis, the etched cross-sectional areas of the specimen are examined through a complete traverse:

The examination focuses on areas unaffected by external processes such as cold working, carburization, or welding. Any evidence of these conditions must be noted in the test report to account for their potential influence on the observed microstructure.

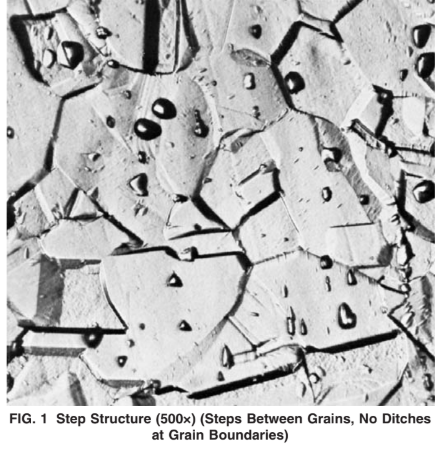

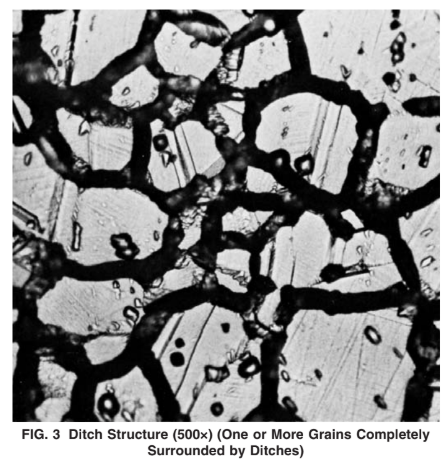

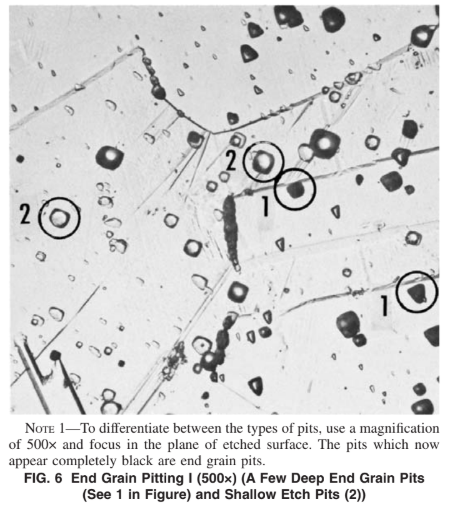

The observed etched structures are categorized into distinct classifications based on their features. Each classification provides insights into the material's susceptibility to intergranular attack.

This classification system provides a structured and reliable method for interpreting the etched microstructures of austenitic stainless steels. The distinctions between these classifications enable engineers and material scientists to make informed decisions about the material's performance and suitability for specific applications.

The assessment of etched structures showing only steps or those with grains completely surrounded by ditches in every microscopic field can typically be carried out rapidly. These classifications are straightforward:

In cases where the structure appears to be a dual structure, however, more extensive examination is required. The primary objective is to identify whether any grain is entirely encircled by ditches. If even a single encircled grain is observed, the specimen must be classified as a ditch structure, indicating susceptibility to attack.

On stainless steel castings and weld metal, the steps formed between grains through electrolytic etching with oxalic acid are often less prominent compared to those observed in wrought materials. In some instances, these steps may be entirely absent. Despite this, any susceptibility to intergranular attack in such materials is readily apparent through the presence of pronounced ditches. This characteristic provides a reliable marker for evaluating castings and welds, even when step structures are minimal or absent.

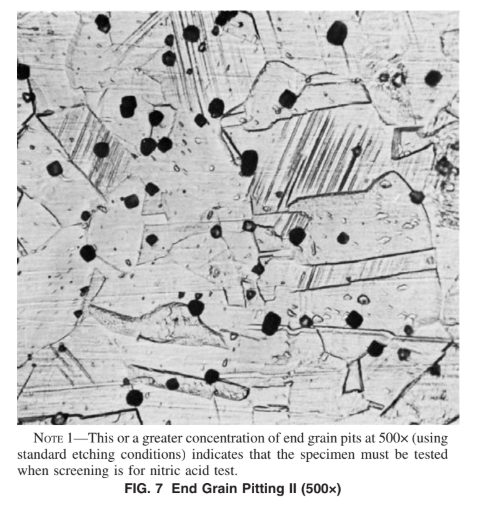

Certain wrought specimens, particularly those prepared from bar stock, may display a random pattern of pits. These pits require careful evaluation to determine their significance:

The Oxalic Acid Etch Test plays a vital role in the rapid screening of austenitic stainless steels for susceptibility to intergranular corrosion (IGC). While it is not a definitive rejection criterion, its ability to classify materials efficiently—distinguishing between acceptable and suspect specimens—makes it a valuable tool in corrosion testing. By pre-screening materials before subjecting them to more time-intensive hot acid immersion tests, this method significantly reduces testing costs and enhances productivity.

Its effectiveness is maximized when used alongside other evaluation methods, such as the Ferric Sulfate-Sulfuric Acid Test, Nitric Acid Test, and Copper-Copper Sulfate-Sulfuric Acid Test. These supplementary tests provide a deeper quantitative assessment of corrosion resistance, ensuring that materials meet stringent industry standards.

By employing a structured classification system for etched structures, the Oxalic Acid Etch Test enables engineers and quality control professionals to make informed decisions about material suitability. Its ability to provide localized insights, particularly for process-affected metals like welds and heat-treated sections, further strengthens its relevance in metallurgical analysis.