December 15, 2024

December 15, 2024

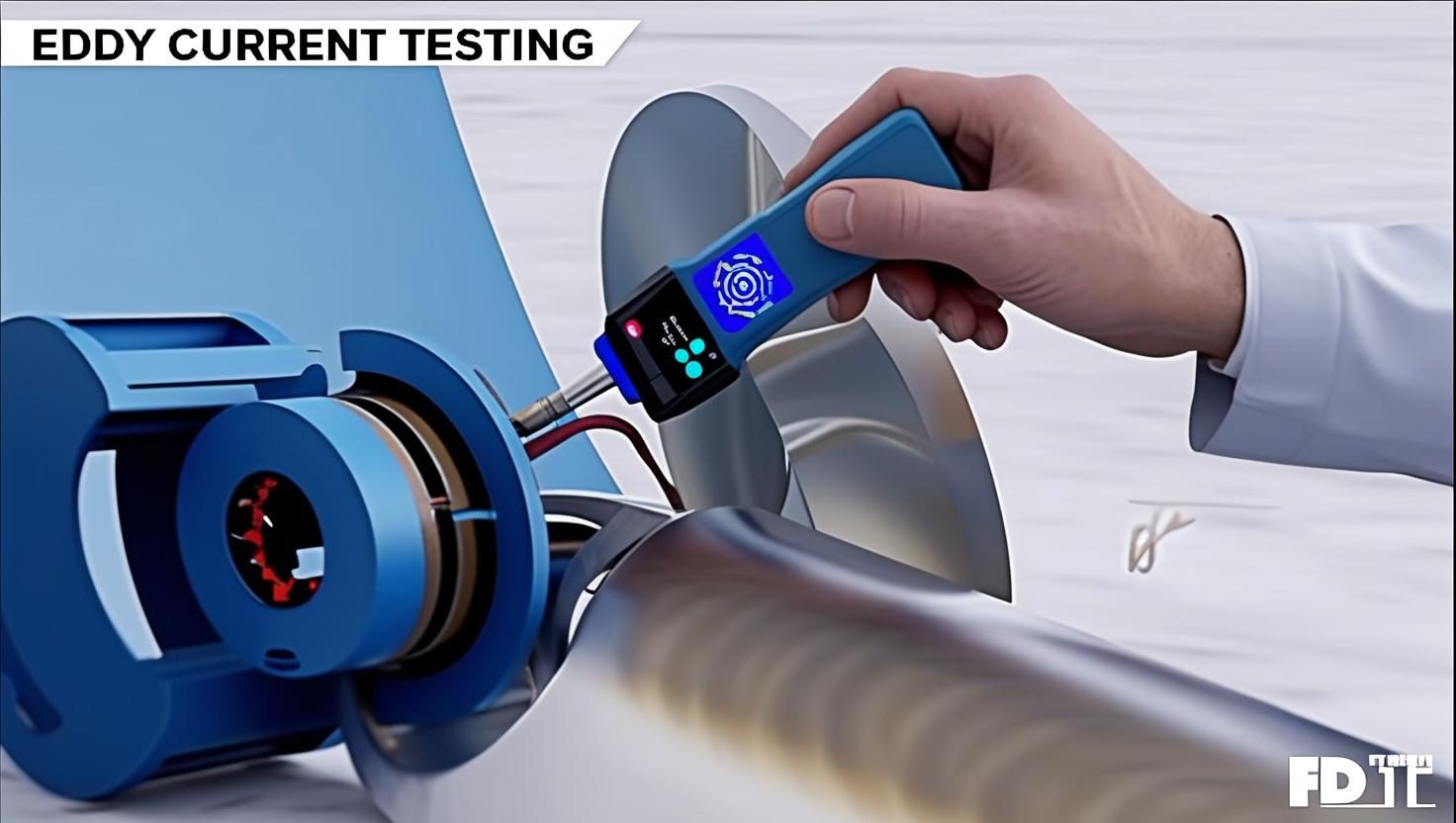

Eddy Current Testing (ECT) is a powerful non-destructive testing (NDT) technique that utilizes the principles of electromagnetic induction to inspect the structural integrity of conductive materials. Its unique ability to detect surface and subsurface flaws, measure material properties, and adapt to various industrial applications has made it an indispensable tool across industries such as aerospace, automotive, and power generation. This article delves into the fundamental principles, advanced methodologies, and cutting-edge research that continue to shape ECT into one of the most versatile and reliable NDT techniques available today.

The foundation of Eddy Current Testing lies in the principle of electromagnetic induction. When alternating current flows through a conductor, such as a copper coil, it produces a fluctuating magnetic field around the coil. This magnetic field adjusts in strength and orientation according to the variations in the alternating current.

When the coil is brought near another conductive material, the fluctuating magnetic field induces eddy currents in the material in compliance with Lenz's Law. These eddy currents form circular loops within the material, generating a secondary magnetic field that opposes the original field from the coil. This interaction provides critical information about the material's condition.

The intensity and behavior of eddy currents are influenced by several material properties:

At the surface of the material, the density of eddy currents is at its highest, making this region most sensitive to defect detection. However, the intensity of these currents diminishes with depth due to the "skin effect," which is influenced by both conductivity and permeability. High-conductivity metals, such as aluminum and copper, exhibit stronger surface eddy current flow, while low-conductivity materials allow deeper penetration.

The depth of eddy current penetration can be controlled by adjusting the frequency of the alternating current:

When inspecting tubes using Eddy Current Testing (ECT), an inspector carefully runs a probe along the length of the tube to identify even the smallest flaws. By utilizing advanced tools, such as pulsed eddy current testing equipment, the technique can also effectively locate surface-level defects in the material. The testing procedure involves a series of systematic steps to ensure accurate flaw detection.

The process begins with the inspector selecting a suitable probe for the test. A commonly used type is the alternating current single-element ETC probe, which is constructed from a conductive wire wound into a coil. This design allows the probe to generate and detect the eddy currents essential for the inspection process.

Once the probe is powered with alternating current, it produces a dynamic magnetic field. This magnetic field is then introduced to the material being inspected. As the inspector moves the probe along the tube, the alternating magnetic field interacts with the conductive material, inducing eddy currents within it. These eddy currents flow in circular loops and are inherently counter to the currents in the probe.

The presence of flaws in the material, such as cracks, corrosion, or thinning, disrupts the flow of these eddy currents. These disruptions cause measurable variations in the eddy current’s intensity and phase. The inspector collects this data during the testing process, using the probe’s sensors to record the changes in the magnetic field.

Once the data has been gathered, it is analyzed to identify and characterize any defects in the material. This step requires specialized expertise, as interpreting the data accurately is critical to determining the nature and severity of the flaws. It is worth noting that the individual responsible for collecting the data during the inspection may not necessarily perform the analysis. Data analysis often requires a higher level of training and certification, which ensures the results are precise and reliable.

By following this methodical approach, Eddy Current Testing allows inspectors to efficiently assess the structural integrity of tubes and other components, ensuring they meet safety and performance standards.

The origins of eddy current phenomena can be traced back to 1824, when François Arago, a prominent scholar, first observed the effect. However, the formal discovery is credited to the inventor Léon Foucault, who in 1855 documented the behavior of eddy currents in conductive materials.

Michael Faraday’s groundbreaking work on electromagnetic induction in 1831 laid the theoretical foundation for Foucault’s discovery. Faraday demonstrated how a changing magnetic field could induce a current in a conductive material, establishing the fundamental relationship between electric currents and magnetic fields. This principle became a cornerstone of Foucault’s research and subsequent discoveries.

Despite these early scientific insights, practical applications for eddy currents were not realized until 1879, when scientist David Hughes demonstrated their utility. Hughes revealed that variations in conductive materials could alter the electrical properties of a coiled wire, paving the way for industrial and scientific uses of eddy currents.

The commercial potential of eddy current testing began to emerge during World War II, when German physicist Friedrich Förster pioneered the development of eddy current NDT techniques. Förster's post-war efforts included founding the Foerster Group, a company dedicated to producing tools and expanding applications for eddy current testing. His contributions helped establish the technique as a reliable and versatile method for non-destructive evaluation.

Today, eddy current testing is a widely used NDT method, known for its precision and versatility. Its long history of producing accurate results has made it an indispensable tool for inspecting and maintaining the structural integrity of critical components in various industries.

Eddy current testing offers numerous benefits, making it a preferred choice for many applications. One of its most significant advantages is its ability to detect extremely small surface and near-surface flaws, including cracks as small as 0.5 mm. This high sensitivity ensures that even minor defects can be identified before they compromise structural integrity.

Another notable advantage is its capability to inspect through multiple layers, including non-conductive surface coatings, without interference from planar defects. This feature is particularly beneficial in industries where coatings or layers are common, such as aerospace and automotive manufacturing.

As a non-contact inspection method, ECT is ideal for assessing components in challenging environments, such as underwater or at elevated temperatures. Its non-invasive nature ensures that the test material remains intact while still providing accurate results.

ECT is also highly adaptable to complex geometries, allowing for effective testing of irregularly shaped objects such as turbine blades, engine disks, and boiler tubes. The ability to automate the inspection of uniform components, such as wheels and heat exchanger tubes, further enhances its efficiency and applicability.

In addition to its technical capabilities, ECT provides instant feedback, enabling inspectors to make timely decisions about a material's condition. The preparation process is relatively quick, as it does not require the use of couplants, and surfaces need only minimal cleaning before testing begins.

Despite its many advantages, eddy current testing does have some limitations. A key drawback is that it can only be applied to conductive materials, limiting its use in certain scenarios where non-conductive materials require evaluation.

Another challenge arises when testing welds in ferromagnetic materials. These materials are highly susceptible to changes in magnetic permeability, which can make the results less reliable. However, advancements in digital fault detectors and specialized probe designs have mitigated some of these challenges.

ECT also struggles to detect flaws that run parallel to the surface of the test object. Since the eddy currents flow parallel to the material's surface, certain defects may go undetected if they are aligned in the same direction.

A further limitation is the need for a reliable power source. Without power, the probes and associated equipment cannot function, potentially limiting its deployment in remote or inaccessible locations.

Finally, the varying magnetic permeability of certain materials can pose challenges during inspections. For example, ferromagnetic materials can exhibit inconsistent permeability, which may affect the accuracy of the test results. Similarly, the effects of permeability on welds in these materials can make ECT non-conductive in some cases, requiring alternative NDT methods.

Eddy Current Testing encompasses a variety of techniques, each tailored to specific applications and inspection needs. Below are some of the most commonly employed methods, along with their unique features and advantages:

1. Eddy Current Array Testing

Eddy Current Array (ECA) testing uses an arrangement of electrically charged coils to create a detailed sensitivity profile for detecting flaws in the material being inspected. This technique allows for the simultaneous evaluation of multiple regions, significantly improving efficiency and coverage. However, careful calibration and probe positioning are essential to minimize mutual inductance between the individual coils, which could otherwise compromise the accuracy of the results.

2. Heat Exchanger Testing

Heat exchanger inspections are among the most widespread applications of eddy current testing. During this process, probes are passed through the metal tubes of heat exchangers to identify flaws such as corrosion, pitting, and thinning. The method offers rapid, real-time feedback, allowing inspectors to gather precise data in a single pass. This efficiency makes it a critical tool in the maintenance of industrial equipment like boilers and condensers.

3. Lorentz Force Eddy Current Testing

Lorentz Force Eddy Current Testing leverages multiple direct current (DC) magnets to overcome the limitations of the skin effect, which restricts eddy current penetration depth. By combining the use of these magnets with controlled relative motion, this method enables quick and accurate inspections, even in scenarios where conventional eddy current testing might struggle. It is particularly effective for detecting subsurface flaws while maintaining high sensitivity.

4. Surface Array Testing

Surface Array Testing is commonly employed in the aerospace industry due to its exceptional ability to measure conductivity, assess corrosion, and evaluate wall thickness with high precision. This technique is versatile and well-suited for inspecting complex geometries and hard-to-reach areas where other inspection methods may fall short. The flexibility of surface array probes makes this approach invaluable for tasks like assessing aircraft structures and detecting hidden defects.

Eddy current testing equipment is broadly categorized into two main components: probes and instruments. Probes are responsible for collecting data during inspections, while instruments process this data and convert it into readable and interpretable results for analysis.

Eddy current probes are available in a wide variety of sizes, shapes, and configurations, offering versatility for diverse testing applications. One of the key advantages of eddy current inspection is the ability to customize probe designs to suit specific requirements. The classification of probes is typically based on the design and operational mode of their test coils. Additionally, how these coils are packaged to achieve optimal coupling with the test area is referred to as the probe's configuration.

Examples of probe configurations include bobbin probes, which are inserted into pipes to inspect them from the inside, and encircling probes, where the coils wrap around the pipe for external inspection. These configurations allow inspectors to choose the most suitable probe for the task at hand.

Absolute Probes

Absolute probes are among the most commonly used types and consist of a single test coil. This coil generates eddy currents and detects variations in the eddy current field. When alternating current flows through the coil, it creates a fluctuating magnetic field both within and around the coil. When the probe is brought close to a conductive material, this magnetic field induces eddy currents within the material.

The formation of eddy currents consumes energy from the coil, leading to a measurable increase in the coil’s electrical resistance. Additionally, the eddy currents produce their own magnetic field, which opposes the field created by the coil, altering its inductive reactance. These changes allow absolute probes to detect flaws, measure conductivity, account for liftoff variations, and assess material thickness.

Absolute probes are highly adaptable and are frequently used in various applications due to their simplicity and reliability. Many commercially available absolute probes include a fixed reference coil—commonly referred to as an "air-loaded" coil—to compensate for changes in the surrounding temperature, ensuring accurate measurements.

Differential Probes

Differential probes are equipped with two active coils, which are often wound in opposition. These coils may also be wound in addition to achieving similar effects. When both coils inspect an area without defects, no differential signal is produced, as the coils detect the same response from the material. However, when one coil is positioned over a flaw and the other is over an unaffected region, a differential signal is generated.

The high sensitivity of differential probes to localized flaws makes them extremely effective for defect detection. At the same time, they are relatively insensitive to gradual changes in properties such as temperature or material dimensions, which can help minimize noise. Additionally, differential probes are less affected by probe wobble, enhancing their reliability in practical applications. However, one notable challenge with this type of probe is the complexity of interpreting its signals, which may require advanced expertise.

Reflection Probes

Reflection probes, also known as driver/pickup probes, consist of two coils with distinct functions. One coil, referred to as the driver, generates the eddy currents in the material, while the other coil, the pickup coil, detects changes in the eddy current field caused by flaws or material inconsistencies.

One of the primary advantages of reflection probes is the ability to independently optimize the driver and pickup coils. For example, the pickup coil can be designed to be small and highly sensitive to detect minute flaws, while the driver coil can be constructed to create a strong and uniform magnetic field close to the test area. This flexibility makes reflection probes a valuable tool for detailed inspections requiring precise flaw detection and field uniformity.

Probes and instruments form the cornerstone of Eddy Current Testing (ECT) systems, each designed for specific functions and applications. Probes are the primary tools for generating and detecting eddy currents, while instruments process the collected data into interpretable formats. Below is an overview of the classifications and functions of probes and instruments used in ECT.

Eddy current probes are available in various designs tailored to specific testing scenarios. They are categorized based on their operational purpose and configuration:

Handheld Probes

Handheld probes are among the most widely used in ECT. These versatile probes are applicable across many industries and are often equipped with interchangeable probe tips and handles. This adaptability makes them suitable for diverse testing needs, from basic flaw detection to more complex inspections.

Surface Array Probes

Surface array probes are specially designed for surface array testing, where the inspection involves surfaces that are irregular or not entirely flat. These probes are particularly useful for inspecting intricate geometries, such as turbine dovetails, and can detect even the smallest surface defects with precision.

Tubing Array Probes

Tubing array probes are primarily used for inspecting tubes in industrial systems. These probes are highly efficient, capable of collecting comprehensive data about the tube’s condition in a single pass. They are indispensable for applications requiring rapid and accurate assessments of tubing integrity.

Instruments play a crucial role in processing the data collected by probes. They translate the raw signals into actionable insights for defect identification and characterization. The following are commonly used instruments in ECT:

Handheld Eddy Current Testing Instruments

These portable devices offer inspectors increased flexibility during testing. Handheld instruments are easy to transport and provide reliable data collection capabilities, making them suitable for on-site inspections across a wide range of industries.

Modular Eddy Current Testing Units

Modular ECT units are compact and portable systems designed for specific applications, such as inspecting condensers and steam generators. Their lightweight design ensures ease of use while maintaining high levels of accuracy and efficiency.

Eddy Current Testing is a versatile method capable of identifying a wide range of material flaws. Below are some of the most common defects detected through ECT:

Specialized Applications

ECT is often used in weld inspections, particularly for assessing surface cracks on weld caps and heat-affected zones (HAZ). This process is often complemented by ultrasonic NDT methods for detecting subsurface flaws. Additionally, ECT is utilized to measure electrical conductivity, which can classify alloys, identify ferrous and non-ferrous materials, and verify heat treatment processes.

Surface examinations are another key application of ECT, where the technique excels in detecting surface cracks in manufactured items and metal stock. For instance, ECT can inspect the areas around aircraft fasteners, ensuring the integrity of critical components.

ECT is also highly effective in corrosion detection. By employing low-frequency probes, inspectors can identify corrosion on the interior of thin metal sheets, such as the aluminum used in aircraft skins. This capability extends to detecting corrosion present in second and third layers of metal, even when it is invisible to ultrasound.

The Eddy Current Array (ECA) technique employs a series of eddy current sensors or coils arranged in a multiplexed configuration to provide comprehensive coverage and heightened sensitivity. These sensors can be configured in various forms, such as flexible arrays, cushioned designs, or spring-loaded fingers, to adapt to different testing scenarios.

ECA systems often incorporate multi-frequency techniques, enabling the inspection of test objects using multiple central frequencies simultaneously. This capability ensures more thorough inspections by allowing the operator to adjust for different material properties and defect types.

Once data is collected, advanced software tools analyze the results. These tools allow users to apply filters and other procedures to emphasize or obscure specific features, improving the clarity and accuracy of defect detection.

Research and innovation continue to drive advancements in eddy current measurement techniques, opening up new possibilities for higher accuracy and efficiency. Below are some of the most promising developments in this field.

Photoinductive imaging, developed at the Center for Nondestructive Evaluation (CNDE), is a cutting-edge, high-resolution scanning and imaging technology. This method utilizes standard-sized eddy current sensors but enhances their capabilities to achieve microscopic resolution. The technology relies on a medium-power argon ion laser with a nominal output of 5 W to create PI imaging probes and equipment.

These advanced probes are particularly effective for inspecting cracks, welds, and diffusion bonds in metallic specimens. By leveraging the laser's precision, photoinductive imaging produces detailed, high-resolution images, making it a powerful tool for applications requiring meticulous defect analysis.

Pulsed eddy current testing is another area of active research that is reshaping the field. This technique is highly effective for detecting and quantifying corrosion and cracking in multi-layered aluminum structures, such as those used in the aerospace industry. Unlike traditional methods, PEC testing uses broadband pulse signals, allowing it to capture data from various depths within a material.

The skin effect, which causes eddy currents to concentrate near the surface, gives pulsed eddy currents a unique advantage. Each pulse contains a spectrum of frequencies, enabling comprehensive depth analysis. The low-frequency components of the pulse provide remarkable penetration depth, allowing the inspection of deeper flaws while simplifying data interpretation compared to multi-frequency techniques.

Applications of PEC testing have demonstrated its potential in identifying material loss due to corrosion in multi-layer aluminum assemblies. Recent studies have shown its effectiveness in detecting cracks originating from fasteners and measuring case depth in hardened steel samples. The ability to analyze ferromagnetic materials further broadens its scope, making it a versatile solution for challenging inspection scenarios.

Eddy Current Testing stands at the forefront of non-destructive evaluation, offering unparalleled precision and adaptability. From its roots in the principle of electromagnetic induction to its applications in detecting flaws, corrosion, and material wear, ECT continues to evolve through advancements such as photoinductive imaging and pulsed eddy current testing. These innovations ensure that ECT remains a cornerstone of modern industrial inspection, addressing challenges with increasing accuracy and efficiency. As research continues to refine its capabilities, ECT is poised to play an even greater role in ensuring safety and reliability in critical infrastructure and components.